1. Project Introduction

UAE AK Company owns a lime production plant. The plant required one set of positive pressure pneumatic transmission system. The system would transport the quick lime to the silo for the storage. It is bidding equipment. The technical parameters and model selection of the positive pressure pneumatic transmission system have not yet been determined.

2. Project Description

After the customer disclosed the technical requirements to us, the technicians from Henan Zhengzhou Mining Machinery Co.,Ltd (ZK Corp) quickly gave a solution according to the customer's existing production situation. The solution includes detailed equipment parameters, shape drawings and layout drawings. The detailed proposal and quick reply from ZK Corp had given the customer a very professional first impression.

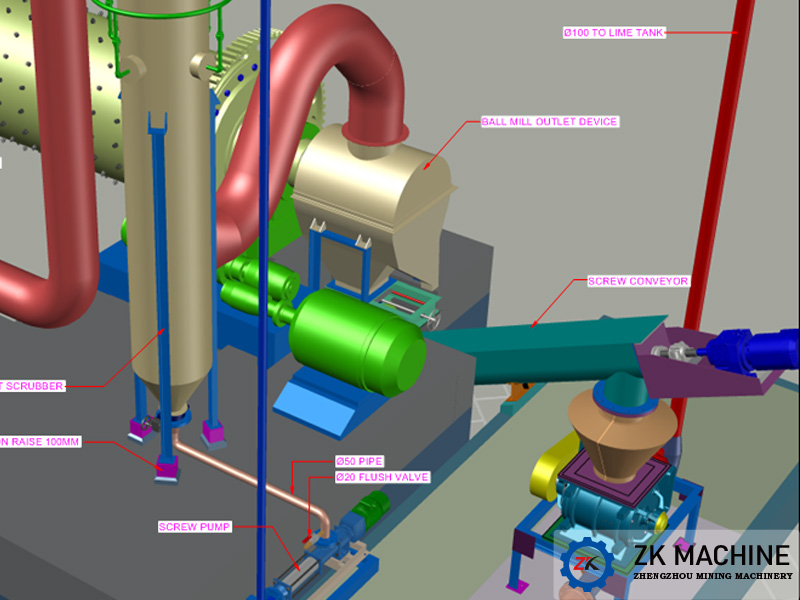

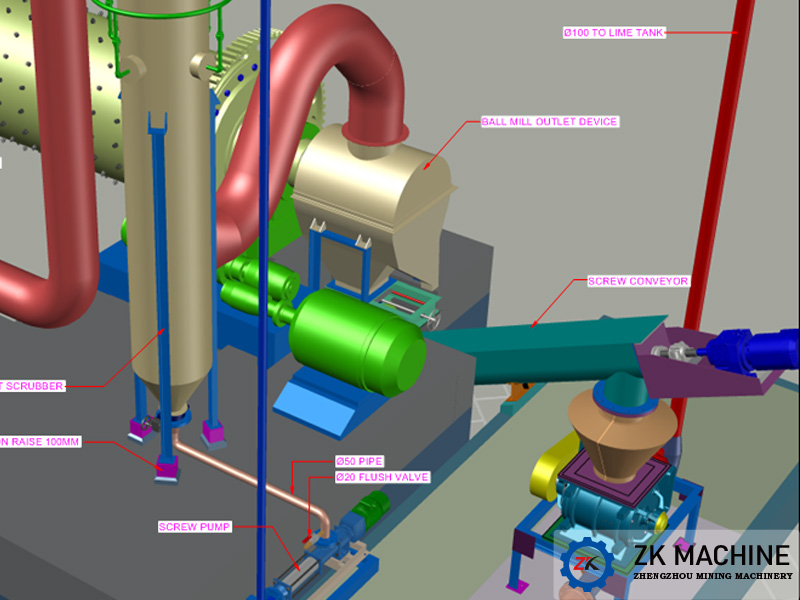

After one month of research, discussion, calculation and 3D layout design with the customer's technical staff, the final proposal had been finalized. Meanwhile, ZK Corp’s technician also helped customers solve many other technical problems during the production. Finally, the technical parameters such as size, transportation capacity, steel material, air volume, air pressure, installation angel and power are determined. Mutual trust had been greatly deepened. At the same time, the equipment technical parameters with reasonable price submitted by our company were recognized by the final user side, and finally ZK Corp won the equipment of this bidding section.

After one month of production, the positive pressure pneumatic transmission system equipment was tested in the assembly workshop of Henan Zhengzhou Mining Machine Co., LTD., and passed the quality and function test of the third party inspection company in one time. One-time acceptance highlights the Henan Zhengzhou Mine Machinery Co., LTD. "Quality of survival" business philosophy. Make delivery as the contract requirements showing Henan Zhengzhou Mining Machinery Co., LTD. "Timely delivery" commitment to customers.

3. Equipment Parameter

Item No.

| Item Name

| Type or Model

| Unit

| Qty

|

|

1 | Positive Pressure Pneumatic Transmission System | Model: QLSR-15 | SET

| 1 |

1.01 | Roots Blower | Model: HTSR-125L | PC

| 1 |

|

| Air volume: 12.95 m3/min |

|

|

|

| Pressure: 58.8KPa |

|

|

|

| Including: fan body, motor, inlet and outlet slicer, spring joint, single direction valve, safety valve, pressure meter, bottom seat. |

|

|

1.02 | Air Exhaust Room | Model: V-12-C | PC

| 1 |

1.03 | Rotary Feeder

| Model: ARG300 | PC

| 1 |

|

| Diameter: DN300 |

|

|

|

| Including main body, gear motor, bottom base, chain pulley, chain, cover, air sealing device for shaft, surfacing on the end of rotor. |

|

|

1.04 | Accelerating Chamber | Model: FZ12 | PC

| 1 |

1.05 | Flat Valve | Model: 300x300 | PC

| 1 |

1.06 | Bag Filter | Model: ZM32(A) | PC

| 1 |

|

| Air volume: 1500m3/h |

|

|

|

| Total filtering area: 24m2 |

|

|

|

| Cleaning compressed air pressure: 0.5-0.7MPa |

|

|

|

| Cleaning compressed air consumption: 0.1m3/min |

|

|

|

| Bearing negative pressure: 5000Pa |

|

|

|

| Pulse valve quantity: 4 pcs |

|

|

1.07 | Inclined Screw Conveyor | Model: LSY300x4m | PC

| 1 |

|

| The distance between inlet and outlet: 2040mm |

|

|

4. Project Picture