1. Project Overview

A company from Pakistan has the high reserves of high-quality magnesite mineral with the following chemical composition:

Item 项目 | Al2O3 | SiO2 | Fe2O3 | TiO2 | CaO | MgO | L.O.I 烧失量 |

Magnesite 菱镁矿 | 0.18% | 1.11% | 0.61% | 0.04% | 1.00% | 46.66% | 50.25% |

According to market demand, the Company would like to calcine the magnesite to improve the MgO composition. High purity magnesium oxide has a great market demand, its main application are as follows:

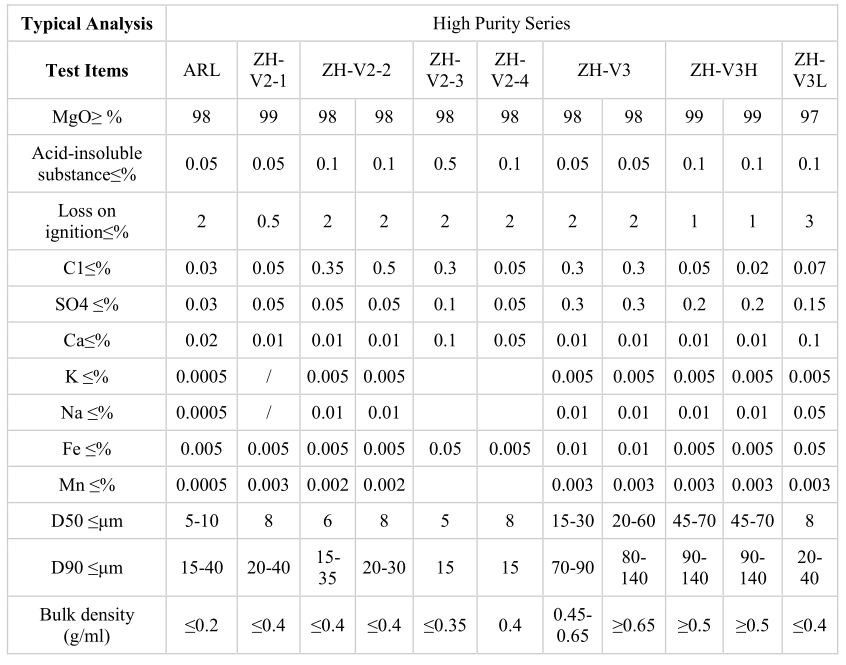

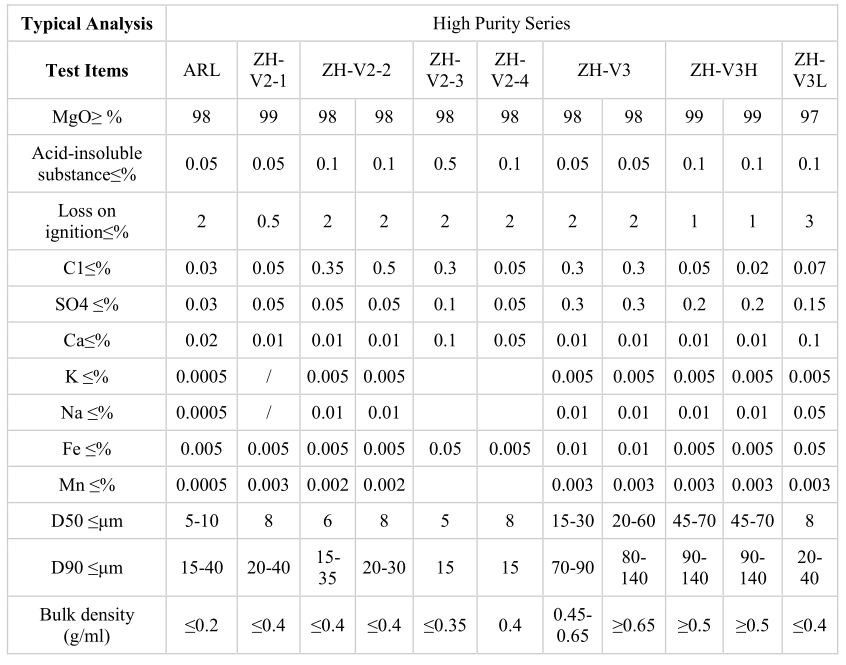

The DBM has the very widely market. It can be used in High Purity Series:

ZH-ARL is high purity product mainly used for camouflage coatings, chemical reagent, ceramics.

ZH-V2-1 is mainly used for microwave dielecdtric ceramics, magnesium lactate, thermal conductive plastics, rubber, copple, etc.

ZH-V2-2 is mainly used for microwave dielectric ceramics, crayon, desiccant, enamel etc.

ZH-V2-3, ZH-V2-4 These models are used for petroleum catalyst.

ZH-V3 is mainly used for acrylic acid magnesium, medical intermediates, microwave dielectric ceramics, liquid crystal glass etc.

ZH-V3H is high purity product mainly used for phosphating solution, magnesium stearate, vinegar tablets, liquid crystal glass, petroleum catalyst, styrene-acrylic emulsion, cosmetics, magnesium aspartate etc.

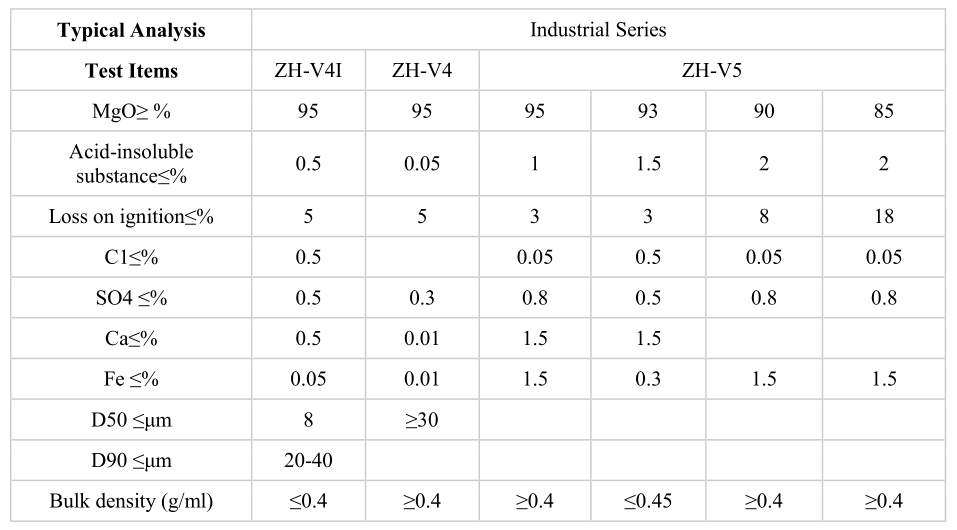

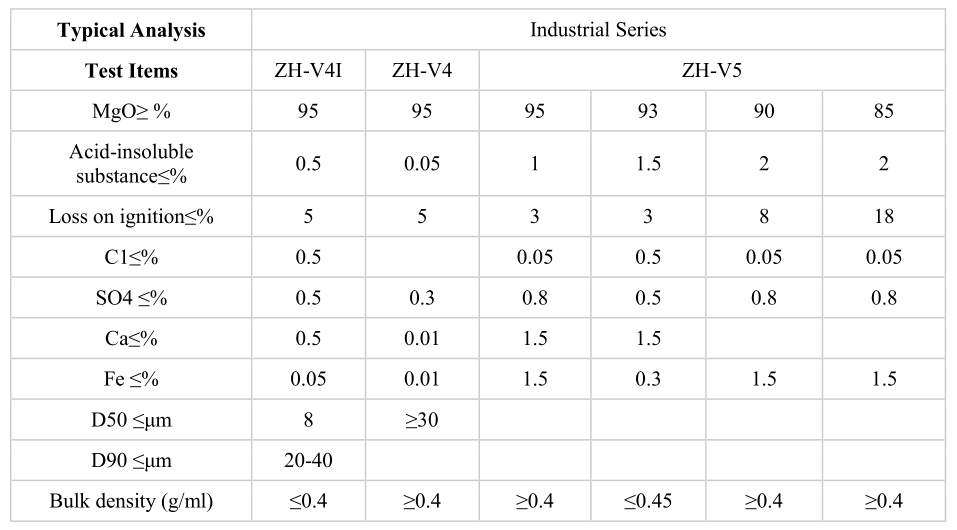

2. Industrial Series

2. Industrial Series

ZH-V4I is mainly used for manhole covers, nitrile rubber foam, sillicone rubber, CPE magnesium oxide, magnesium stearate, dental impression material etc.

ZH-V4 is used for mictrowave dielectric ceramics.

ZH-V5-1 is 95% purity used for cement accelerator, water treatment etc.

ZH-V5-2 is 93% purity used for potassium monopersulfate.

ZH-V5-3 is 90% purity used for desillication, water treatment etc.

ZH-V5-4 is 85% purity used for is desillication, water treatment etc.

3. Project Engineering Concept

According to the laboratory test, The most suitable calcination temperature and process route were found. The engineering of the whole factory process flow and the manufacturing of equipment shall have a reasonable and reliable basis. Bag dust collector is used to treat the flue gas of kiln tail and achieve standard emission.

Project Implementation:

The particle size of magnesite obtained by crushing and screening is 30-60mm, and then the qualified particle size of magnesite is sent into the dumping hopper by front loader. A bar valve is set below the dumping hopper to control the discharge volume of the raw material. The material in the dumping hopper is fed into the bucket elevator by belt conveyor. The bucket elevator lifts the material to the buffer silo. The buffer silo plays a guarantee role in the stable production of follow-up equipment. At the same time, it shall convenient the front feeding equipment maintenance work. The buffer silo is equipped with bar valve to control the discharge volume, and the belt scale weigher is set under the valve for accurate and uniform feeding. The material enters the rotary kiln through the double - layer double - door hammer air lock valve through the heat - resistant chute. Double - layer double - door hammer lock valve plays the role of air lock. The material successively passes through the preheating zone, calcining zone and cooling zone of the rotary kiln. The axial fans are arranged outside the calcining zone to control the temperature of kiln skin and protect the kiln body. The material calcined by the rotary kiln enters the rotary cooling machine through the chute of the kiln head. Rotary coolers makes the heat exchange with air to cool the material. After cooling the material through the bucket elevator into the final product silo for storage. Bag filter is set on the top of final product silo to control dust emission. The bar valve is set under the final product storage silo to facilitate the subsequent packaging and transportation.

The burner adopts oil-gas integrated burner, which has flexible operation and strong adaptability, and can be applied to fuel oil and gas. Burner operation is safe, stable, reliable and energy saving. The burner is equipped with roots blower to provide primary air. In the cooling machine, the air heated by heat exchange enters the rotary kiln as a secondary air to participate in combustion, so as to realize the purpose of energy saving.

For the flue gas discharged from the end of the kiln, it firstly enters the cyclone dust collector for settling the larger particles in the flue gas. Then the gas enters the mechanical air cooler. The mechanical air cooler forces the flue gas to cool down to protect the bag dust collector behind it. The cold air valve is also provided before entering the bag dust collector, which plays a role in reducing the flue gas temperature as the last insurance. Bag filter adopts FMS high temperature resistant filter bag, which can achieve high filtration efficiency and achieve standard emission. High temperature fan is set after bag filter to provide negative pressure operating environment for the whole calcining system.

4. Technical Parameter of Main Equipment

Item No.

设备位号 | Item Name

设 备 名 称 | Type or Model

规格或型号 | Unit

单位 | Qty

数量 |

|

|

RAW MATERIAL FEEDING SYSTEM

上料系统 |

|

|

|

1.01 | Bar Gate

棒条阀 | Model: BTF4040

型号:BTF4040 | Unit

台 | 1 |

|

1.02 | Belt Conveyor

带式输送机 | Model: B500×3m

型号:B500×3m | Unit

台 | 1 |

|

1.03 | Ring Chain Type Bucket Elevator

环链式斗式提升机 | Model: TH250×30m

型号:TH250×30m | Unit

台 | 1 |

|

1.04 | Bar Gate

棒条阀 | Model:BTF4040

型号:BTF4040 | Unit

台 | 1 |

|

1.05 | Quantitative Belt Feeder

带式定量给料机 | Model: DEL500×2m

型号:DEL500×2m | Unit

台 | 1 |

|

1.06 | Bag Filter

仓顶除尘器 | Model: ZM48(A)

型号:ZM48(A) | Unit

台 | 1 |

|

CALCINATION SYSTEM

煅烧系统 |

|

|

|

2.01 | Double Layer Heavy Hammer Air-lock Valve

双层双门重锤锁风阀 | Model: FBF4040(Ⅱ)

型号:FBF4040(Ⅱ) | Unit

台 | 1 |

|

2.02 | Feeding Chute

入窑溜管 | Model: DN300,L=5m

规格:DN300,L=5m | Unit

台 | 1 |

|

2.03 | Rotary Kiln

回转窑 | Size: Φ2.5×75m

规格:Φ2.5×75m | Unit

台 | 1 |

|

2.04 | Rotary Cooler

单筒冷却机 | Size: φ2.2×30m

型号:φ2.2×30m | Unit

台 | 1 |

|

2.05 | Combustion Roots Fan

助燃风罗茨风机 | Model: RSR-250D

型号:RSR-250D | Unit

台 | 1 |

|

2.06 | Fuel Feeding System

燃料供给系统 | Model: ZYG-1

型号:ZYG-1 | Set 套 | 1 |

|

2.07 | Dual Fuel Burner

双燃料燃烧器 | Model: RSQ-4

型号:RSQ-4 | Set 套 | 1 |

|

2.08 | Flat Gate

平板闸门 | Size: 400×400

规格:400×400 | Unit

台 | 2 |

|

2.09 | Kiln Body Fan

回转窑专用筒体风机 | Model: GZ-6

型号:GZ-6 | Unit

台 | 8 |

|

FINAL PRODUCT CONVEYING

成品输送 |

|

|

|

3.01 | Ring Chain Type Bucket Elevator

环链式斗式提升机 | Model: TH250×30m

型号:TH250×30m | Unit

台 | 1 |

|

3.02 | Bar Gate

棒条阀 | Model:BTF4040

型号:BTF4040 | Unit

台 | 1 |

|

3.03 | Bag Filter

仓顶除尘器 | Model: ZM64(A)

型号:ZM64(A) | Unit

台 | 1 |

|

DUST COLLECTING SYSTEM

收尘系统 |

|

|

|

4.01 | Cyclone Dust Collector

旋风除尘器 | Model: CLP-25.0

型号:CLP-25.0 | Unit

台 | 1 |

|

4.02 | Mechanical Air Cooler

机力空冷器 | Model: KQL-400

型号:KQL-400 | Unit

台 | 1 |

|

4.03 | Motorized Cold Blast Butterfly Valve

电动调节掺冷风蝶阀 | Model: GD943H-0.5C DN500

规格:GD943H-0.5C DN500 | Unit

台 | 1 |

|

4.04 | Bag Filter

袋式除尘器 | Model: PPC128-7

型号:PPC128-7 | Unit

台 | 1 |

|

4.05 | ID Fan

引风机 | Model: Y9-38NO.12.5D

型号:Y9-38NO.12.5D | Unit

台 | 1 |

|

REFRACTORY MATERIALS 耐火材料 |

|

|

|

5 | Refractory material 耐火材料 |

| Tons 吨 | 500 |

|

2. Industrial Series

2. Industrial Series