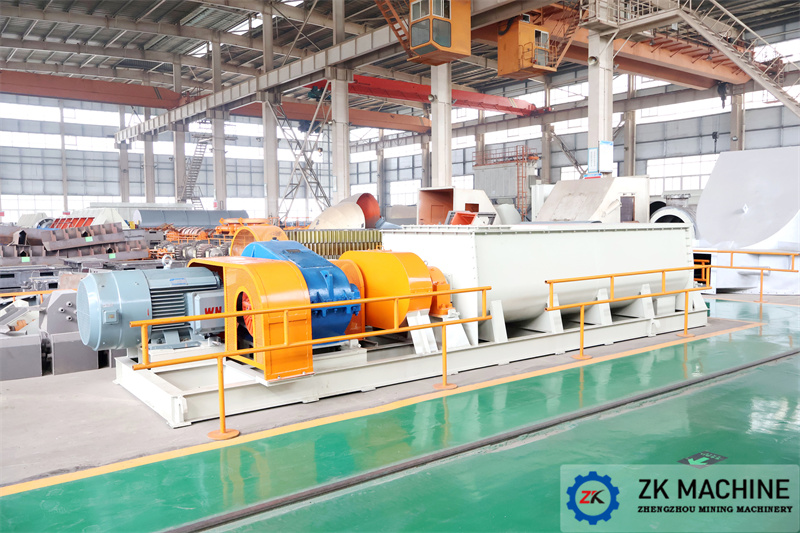

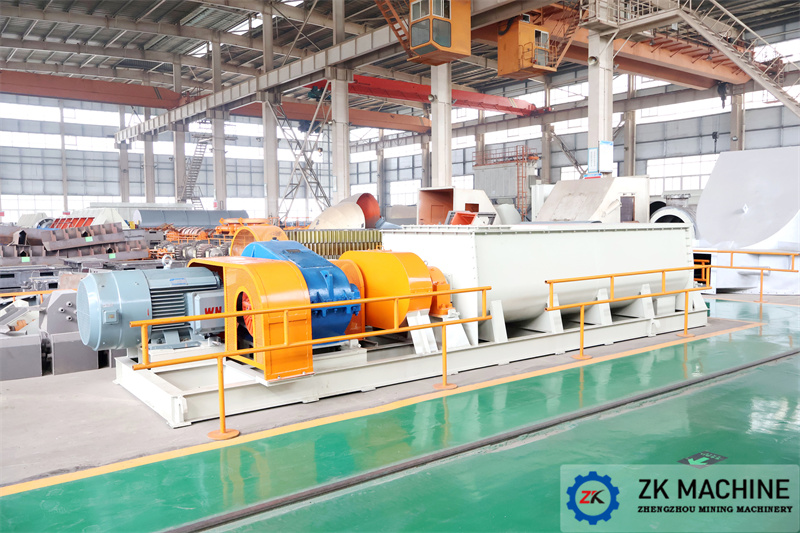

Today, as the environmental protection industry is booming, technological innovation has become a key force in promoting the progress of the industry. Recently, China's leading environmental protection industry company joined hands with Henan Zhengzhou Mining Machinery Co., Ltd. to witness the successful application of the ZJ250×2.1m twin-shaft mixer. This is not only an important breakthrough in the research and development and application of environmental protection technology for both parties, but also a powerful practice of effective and environmentally friendly production models.

As a leader in the field of domestic environmental protection, this customer has a deep state-owned background and is a listed company that has been focusing on the research and development and application of environmental protection technologies for half a century. Its business is spread all over the world, and it is committed to providing a full range of comprehensive ecological and environmental governance solutions. It has been ranked first in the "Top 20 Chinese Air Pollution Control Service Companies" and "Top 50 Chinese Environmental Companies" for many consecutive years. In order to further enhance the project R&D capabilities and meet specific environmental protection treatment needs, the company customized a ZJ250×2.1m twin-shaft mixer from Zhengzhou Mining Machinery, which is specially used to treat fly ash filter press plate frame mud cake with a moisture content of 35%, aiming to improve the processing efficiency and environmental protection standards by effectively mixing, crushing and mixing materials.

Faced with the high requirements of customers, the technical team of Zhengzhou Mining Machinery, carried out in-depth customized design. The ZJ250×2.1m twin-shaft mixer has become an ideal choice due to its unique advantages. The equipment can not only operate in a closed environment and effectively prevent dust leakage, but also integrates multiple functions such as mixing, humidification, and transportation, greatly improving production efficiency and reducing floor space. It is particularly noteworthy that the mixing blades are made of wear-resistant materials and have undergone special surface treatment, making them extremely wear-resistant. The blade angle is adjustable and the number is increased, which can accurately control the mixing time and effect and meet the processing requirements of different material characteristics.