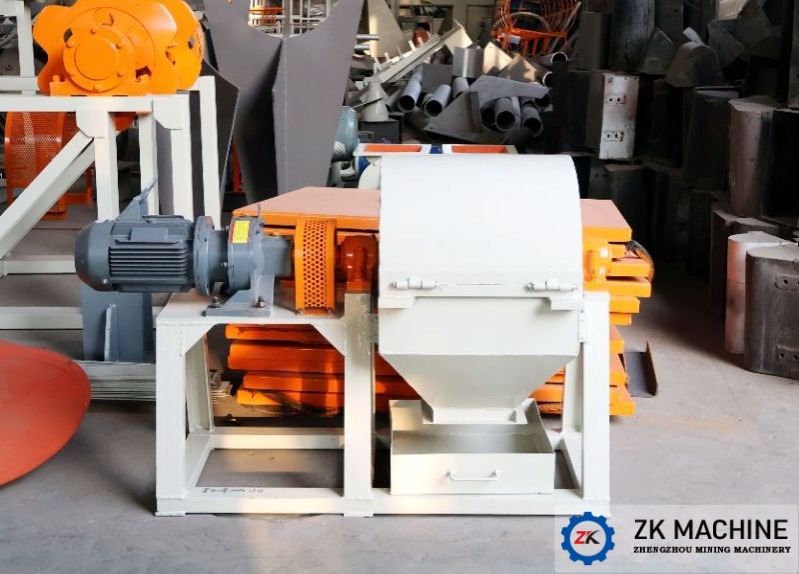

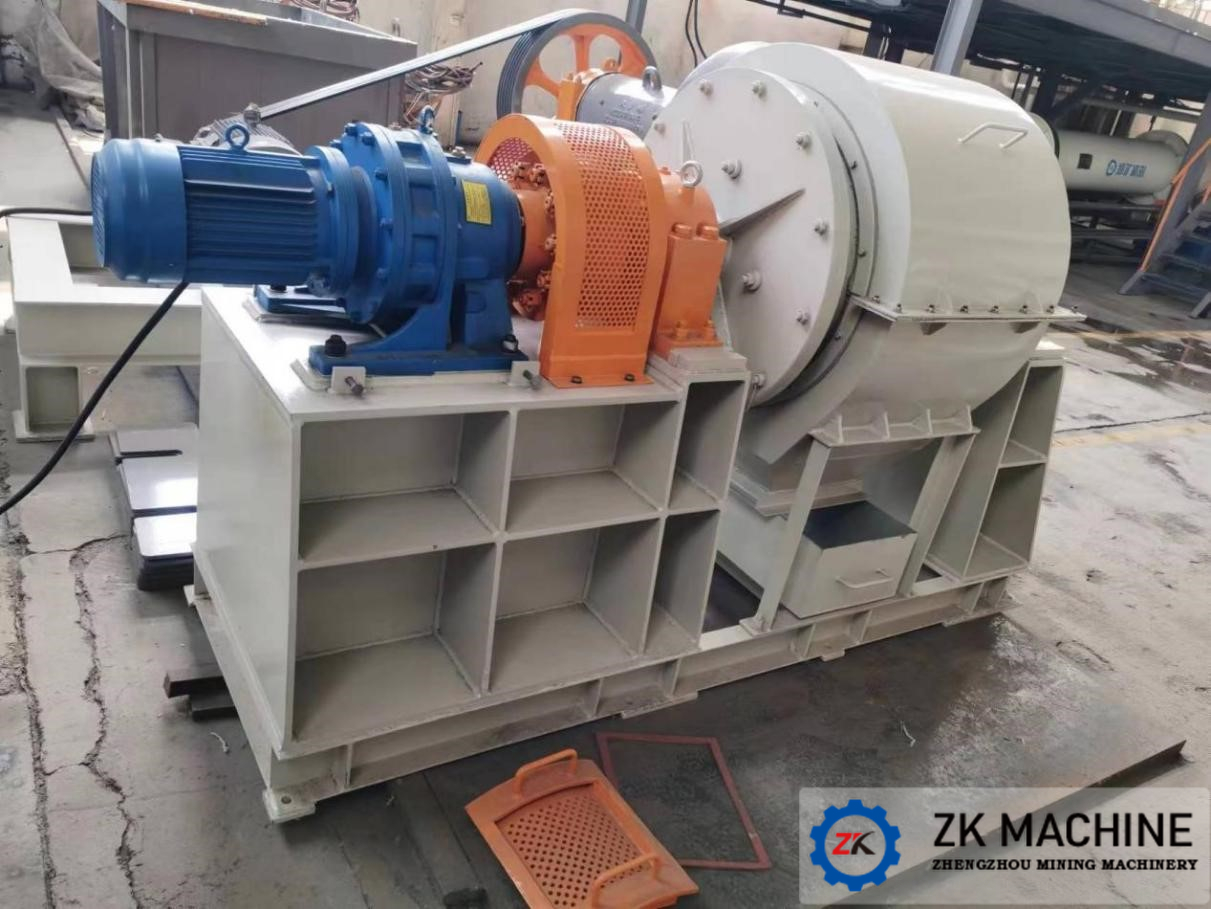

✔ Custom Ball Mill Solutions for Global Industries | 30+ Years Engineering Expertise

As a trusted ball mill manufacturer with 30 years of experience, ZK Corp delivers complete grinding solutions for global industries. From raw material analysis to turnkey installation, we engineer robust ball mills that process over 200+ material types across 15+ industries. our solutions deliver 30% higher grinding efficiency while reducing energy consumption by 25-40% compared to conventional models.

Our ball mills are engineered to process materials with feed sizes ≤25mm, delivering precise output particle size control through optimized grinding media configurations (customizable steel/ceramic/zirconia ball ratios). These ball mills work great for both dry and wet grinding. You can use them to process over 200 different materials - from regular metal ores to high-tech ceramics.

✔ Types of Ball Mills

Classification | Types |

Discharge Method | Grid / Overflow Ball Mills |

Operation Process | Wet / Dry Ball Mills |

Operation Mode | Intermittent / Continuous Ball Mills |

Energy Efficiency | Standard / New Energy-Saving Ball Mills |

Cylinder Ratio | Short / Medium-Long / Long Ball Mills |

✔ Industry Applications

1. Mining: Gold/copper/iron ore processing

2. Construction: Cement, limestone, gypsum grinding

3. Metallurgy: Aluminum, steel slag refinement

4. Chemicals: Fertilizer, pigment production

5. Energy: Coal powder preparation

6. Advanced Materials: Ceramics, refractories, glass

✔ Process Materials

1.Industrial Minerals:Kaolin, Feldspar, Quartz, Quartz Sand, Fluorite, Talc, Barite, Bentonite, Mica, Magnesite, Calcite etc.

2.Construction & Building Materials: Limestone, Gypsum, Clinker, Slag Powder, Granite,Marble, Calcium Carbonate etc.

3.Metallurgical & Metal Processing: Bauxite, Manganese, Spodumene, Steel Slag, Aluminum Powder, Aluminum Powder Paste etc.

4.Industrial Byproducts: Fly Ash, White Ash, Coal Powder, Coal Gangue, Slag etc.

5.Refractory & High-Temperature Materials: Refractory Materials etc.

6.Energy & Fuels: Coal Powder

✔ Technical Advantages

1.Liner of ball mill is made of high-quality wear resistant material with high strength, wear resistance and long working life.

2.Product fineness is adjustable, uniform and high qualified.Widely used in powder-making production line

3.Large capacity and crushing ratio, good sealing performance. It can be adapted to different working conditions.

4.High grinding efficiency, low energy consumption, energy-saving and high capacity, productive and cost effective. Can grind various ores and other materials with dry type and wet type.