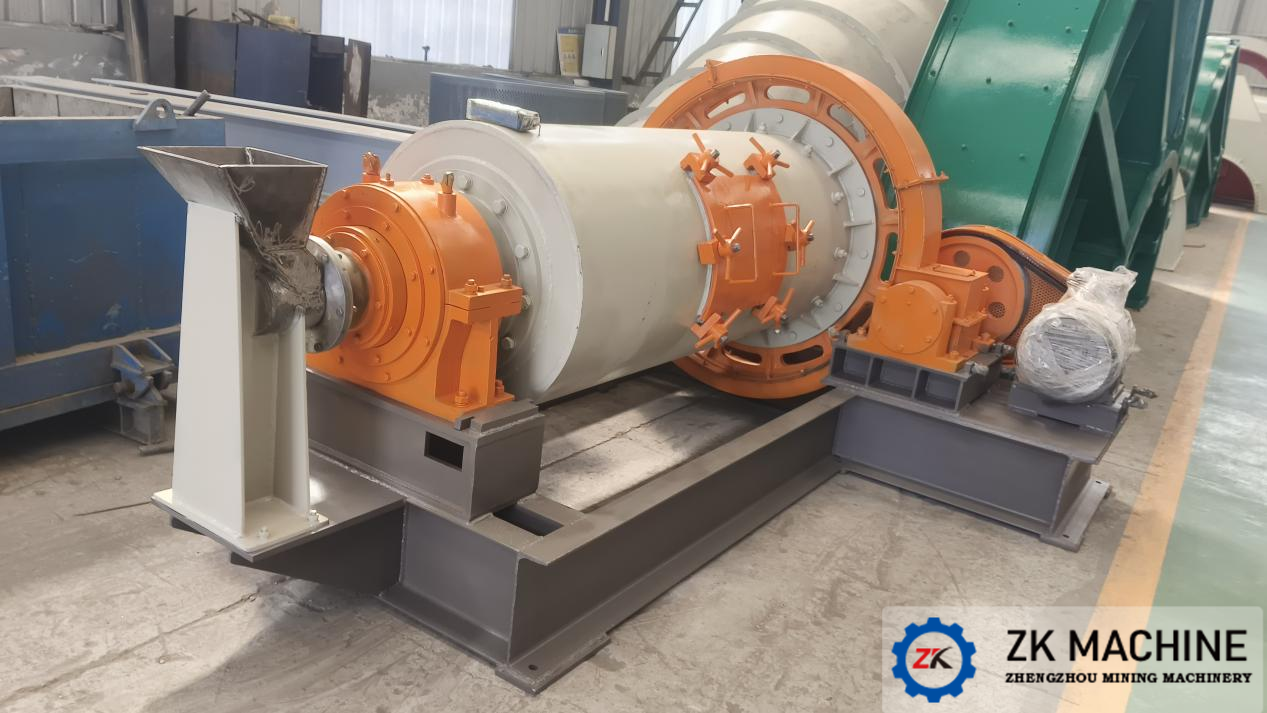

✔ Ceramic Ball Mill (Intermittent/Batch Ball Mill)

A specialized grinding solution for high-precision material processing, ceramic ball mills excel in industrial applications requiring ultra-fine powder production. Featuring dual dry and wet grinding modes, these mills achieve exceptional fineness levels:

1.Dry grinding: Produces ultra-fine powders ranging from 1,000 to 16,000 mesh

2.Wet grinding: Ideal for materials requiring slurry-based processing

✔ Technical Specifications & Features

Nine standardized models with drum diameters from 0.6m to 3.2m

1.Ceramic-lined interior: Ensures contamination-free grinding and material purity

2.Adjustable rotation speed: Operates at 13-50 (r/min)for precise control over particle size

3.Batch processing design: Optimized for small-scale production of specialty materials (e.g., ceramics, pigments, advanced chemicals)

✔ Processing materials

Ceramic ball mill can be used to grind feldspar, quartz, clay, silica and other hard brittle materials.

✔ Advantages

1. After finished material is discharged, another raw material can be put in for grinding, can’t continuous feeding and discharge material.

2. Different liners and grinding media can be used to meet different requirements.

3. The fineness of grinding material depending on milling time.

4. It can be used for wet or dry grinding, finished slurry can pass 1000mesh screen.