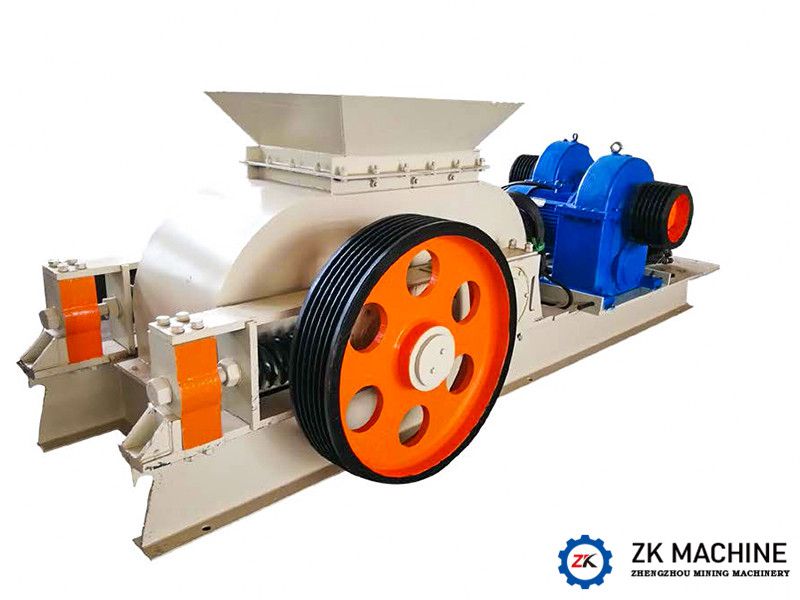

The double-roller crusher is suitable for coarse and intermediate crushing of brittle bulk materials in industries such as cement, chemical, power, mining, metallurgy, building materials, refractory materials, and coal mining. It can handle feed particle sizes up to 32-90mm, with adjustable discharge particle sizes ranging from 2-25mm, and is capable of crushing materials with compressive strength ≤160MPa.

Particularly in the coal industry, this crusher can process raw coal directly after removing iron and impurities—without the need to separate gangue—delivering uniformly sized output with low over-crushing rates. This simplifies the coal preparation process and reduces both investment and production costs.

✔ Double Roller Crusher Specifications

Our double-roller crusher products are categorized by roller diameter and length to meet various production requirements, with capacities ranging from 2-60t per hour. The machine features a simple structure, compact and lightweight design, affordability, reliable operation, and easy adjustment of the crushing ratio. It minimizes over-crushing and is capable of processing sticky and moist materials.

✔ Processing Materials

coal, coal gangue, mining,limestone, guarite, weathered sand, diabase, granite, basalt, tin ore, chrome ore, calcite, glass, ceramics, diabase, zircon, nickel ore, quartz stone, marble, gold ore, coke, petroleum coke, activated carbon, lignite, nickel ore, calcium oxide, coke, River pebble, cobblestone, bentonite, iron ore, bluestone, mountain stone, water slag, steel slag, quartz, shale etc.

✔Application

Applied to the crushing of bulk materials in metallurgy, building materials, mining, highway, mineral processing and other industries.

✔Advantages

1. The roller crusher has the advantages of small size, large crushing ratio, large crushing capacity, low noise, simple structure and convenient maintenance;

2. The crushed materials have uniform particle size, low over-crushing rate, convenient maintenance, sensitive overload protection, safety and reliability;

3. For the coal industry, the machine is used to crush raw coal. As long as the iron and impurities are removed, there is no need to remove the gangue, and the crushed materials can be directly crushed. The particle size is uniform and the crushing rate is low;

4. Simplify the process and reduce investment and production costs.