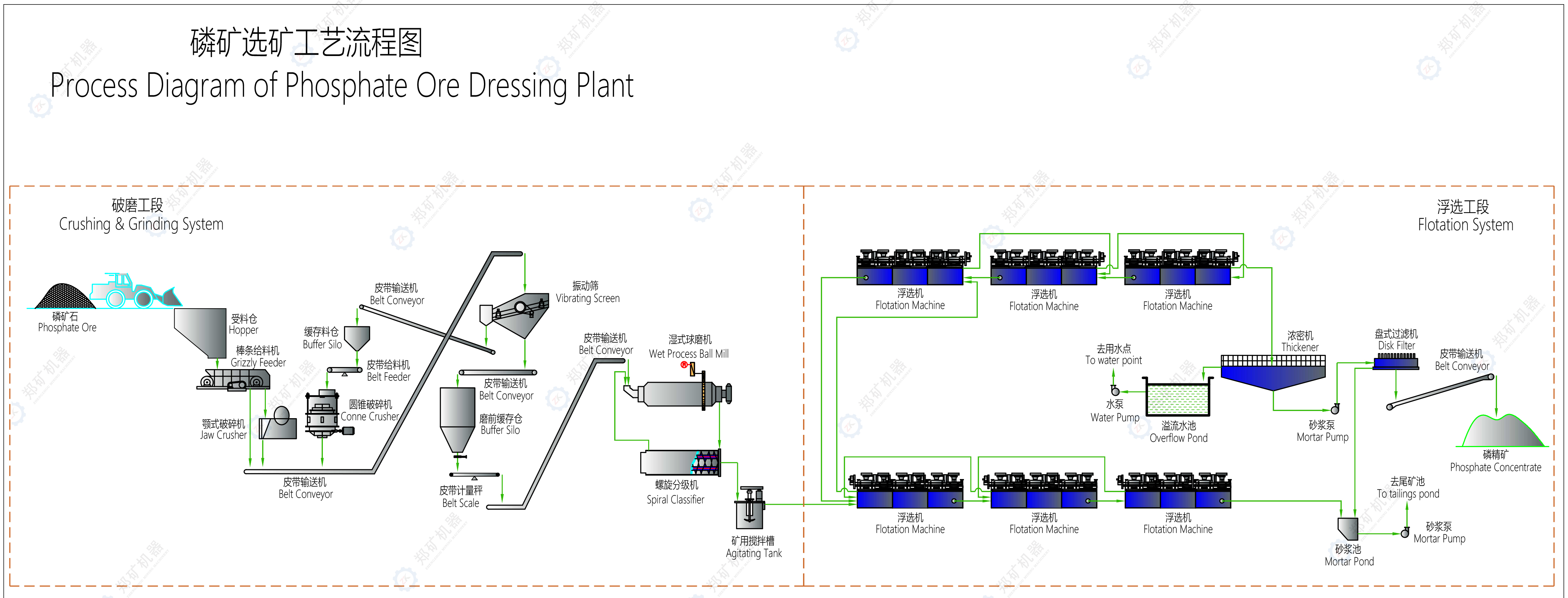

In the process of extracting phosphorus, we need to crush and grind large pieces of phosphate ore into fine powder. Therefore, in the process of mineral processing, we need to use two types of equipment, crusher and ball mill. After being ground into powder, the phosphate ore has high floatability, so it needs to be separated by flotation machines. It can be seen that the phosphate ore beneficiation process mainly includes: crushing and screening, grinding, flotation, dehydration, and tailings treatment. Different stages have different processing processes and different equipment. Let's analyze these stages below.

1. Crushing and screening stage: This stage is mainly to crush large pieces of phosphate ore into small pieces. When crushing, it is necessary to use a secondary closed-circuit or tertiary closed-circuit process to crush the large pieces of phosphate ore of 0-350 mm into small particles of material below 15 mm, and then the subsequent grinding operation can be carried out. The screening operation at this stage is mainly to ensure that the crushed phosphate ore particles are uniform and meet the requirements of less than 15 mm;

2. Grinding stage: The equipment used in this stage is mainly a ball mill. The small pieces of phosphate ore after crushing and screening in the previous stage are fed into the ball mill by the feeder for further grinding. This grinding process is also a closed-circuit grinding. This grinding process can grind the small pieces of phosphate ore into a particle size of 75% of -200 mesh before entering the next production stage;

3. Flotation stage: This stage adopts a single reverse flotation process. After a closed-circuit process of one roughing selection, three fine selections, two scavenging selections and the return of the middling ore, the obtained concentrate is pumped to the concentrate concentrator. There are three commonly used flotation separation methods in this stage: one is to use sodium silicate and starch to inhibit carbonate and other gangue minerals, and use fatty acids as collectors to float out phosphate ore; the second is to add sodium hexametaphosphate to inhibit phosphate ore, use fatty acids to float carbonate gangue minerals first, and then float phosphate ore; the third is to use selective alkyl sulfate as a collector, first float out carbonate minerals, and then use oleic acid to float phosphate minerals;

4. Dehydration stage: This stage is mainly after flotation, and there are two main levels of dehydration: the first stage of dehydration uses a high-efficiency concentrator, and the second stage of dehydration uses a ceramic vacuum filter. These two stages of dehydration can reduce the water content of the phosphate concentrate to less than 12%;

5. Tailings treatment stage: The above-mentioned phosphate ore flotation process will produce tailings, which are pumped to the tailings concentrator, and the bottom flow of the machine is pumped to the tailings filling station. Then it can be recycled according to demand, which can avoid resource waste and environmental pollution;